Time isn't Money. UPTIME is Money!

Time isn't Money. UPTIME is Money!

- Heavy Mill Duty

- Installation in Minutes!

- Up to 50000 PPR

- Removable Sensors

- Wide-Gap Technology, No Air Gap Adjustment Required

- Mounts Securely to Motor

- Outputs Fully Short Circuit Protected

- Self-Diagnostic LED & Alarm Output

- Sealed Electronics

- -40°C to +100°C Operation

- 3 Year No-Hassle Warranty

- Excellent for Gear Motors and Brake Applications

SMARTach™ III Magnetic, Modular Encoder, 8.5" C-Face Mount

SMARTach™ III Magnetic, Modular Encoder, 8.5" C-Face Mount

AV850 SMARTach III heavy mill duty modular magnetic encoders fit standard 8.5" FC-Face motors. Other models, from 115mm to 12.5", are available to fit other motor sizes, and hazardous duty models: XR850 and XPH8 intrinsically safe and SV850 functional safety encoders are also available.

Quite simply, the AV850 is designed to eliminate encoder failures.

All AV850 electronics are fully encapsulated. There are no moving wearing parts. AV850 sensors locate over 4X farther from the rotor than the competition; no more sensor/rotor grinding!

Miswiring an encoder is common– and it shouldn’t cost you time or money. The AV850 has full output short circuit and reverse voltage protection, plus surge protection. AV850 SMARTach III sensors digitally self-tune the outputs to eliminate drive trips caused by poor encoder signals. The universal 5-24V design drives longer cables and is protected against wiring errors.

Adaptive Electronics: At power-up you know you installed it right! The green LED tells you your AV5 Sensor is aligned with the rotor and reading signal. If at any time, the AV5 cannot produce consistent signals, the LED changes to red and the optional remote alarm contact activates. However, the encoder keeps working to give you time to schedule service. Even wiring errors and short circuits that cause an over-temp situation will be detected and indicated by changing the LED to orange.

If you think you need to replace your drives to end your encoder failures, try a better encoder instead. Specify AV850!

Specifications

Operating Power (Each Sensor): 5-24V*

Current: 100mA

Output Format: A Quad B with marker (A,/A, B,/B, Z,/Z)

Frequency Range:

@5V, @1m cable, 250 kHz Max

@24V, @300m cable, #8 output, 45 kHz Max

Maximum Cable Length: 1000'

PPR: 4 - 50000***

Speed: 6000 RPM Max****

Rotor Positioning: Up to +/-0.100" movement/misalignment

Sensor-Rotor Gap: 0.045", +0.015/-0.040" [1.14mm+0.38/-1.0]

Temperature: -40° to 100°C (rotor -40° to 150°C peak)

Electronics: Fully Encapsulated, IP67**

Vibration: 18G

Shock: 1 meter drop test

Weight: 9lbs. [4kg]; 11lbs. [5kg] dual

* Electrical specifications for SMARTach III model (serial #30,000 or higher), consult Nidec Industrial Solutions for earlier model specifications.

** Certain connector options may reduce IP rating.

***(PPR) Standard maximum PPR is 5000. Consult Factory with your application for PPRs up to 50,000.

**** (Speed) Maximum RPM may be limited for PPR > 2,500. Consult Factory with your application.

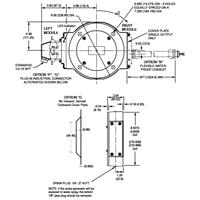

All dimensions are in inches [millimeters].

Specifications and features are subject to change without notice.

More Advantages

- SMARTach II sensors find problems before they cause failure

- Replaces Northstar/LakeShore RIM8500™, NexGen 8500; Avtron M193B, M285; GE AN-DG models

- Resists motor and brake interference noise

- Reverse voltage protection

- Mix and match any PPRs with any rotor

- Permits axial movement up to +/-0.100" [+/-2.54mm]

- Universal rotor for all GE CD style and many Reliance motors.

- Optional overspeed switch

- Optional shaft grounding