STRONGER and SMARTER

STRONGER and SMARTER

- Heavy Mill Duty

- Simple, Secure Installation

- Wide-Gap Technology: No Sensor Scraping or Adjustment

- 4 - 50000 PPR

- No Couplings or Bearings

- Sealed Electronics

- Self-Diagnostic LED and Alarm Output

- Universal 5-24V Operation

- 3 Year No-Hassle Warranty

- Adapters available to fit Euro 85mm B-Flanges

- All models are protected against all short circuits and wiring errors

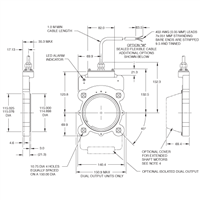

AV115 THIN-LINE III™ heavy mill duty modular magnetic encoders fit standard 115mm flange motors. Adapters are available to fit European B-flange (85mm/100mm BC) motors. Other THIN-LINE III models, ranging from 4.5" to 8.5", are available to fit other motor sizes as needed. For Euro B-flange, AV45 is also available.

AV115 THIN-LINE III™ heavy mill duty modular magnetic encoders fit standard 115mm flange motors. Adapters are available to fit European B-flange (85mm/100mm BC) motors. Other THIN-LINE III models, ranging from 4.5" to 8.5", are available to fit other motor sizes as needed. For Euro B-flange, AV45 is also available.

THIN-LINE III encoders feature simple installation, durable construction, and clear diagnostics to eliminate encoder-related downtime:

First, the magnetic sensors are fully potted to withstand dirt and liquids. No glass disks, no optics to clog. There are no moving, wearing parts! The patented Wide-Gap™ Cam Screw Rotors™ put an end to sensor damage, are simpler to install, and stay securely mounted to the shaft. The universal 5-24V design drives longer cables and is protected against wiring errors and surges.

When you power up an AV115, you know you installed it right: the green light tells you the digital self-tuning has set your AV115 optimally. If at any time, the AV115 cannot produce ideal signals, the light changes to red and the remote alarm contact activates. However, the encoder keeps working to give you time to schedule service. Any time there are wiring errors, the LED changes to orange.

With a real-world installation history of over 4,500,000 hour MTBF, AV115 encoders will keep your machine running 24/7/365!

Specifications

Operating Power: Volts: 5 - 24 VDC; Current: 100mA, no load

Output Format: A Quad B with Marker (A,/A, B,/B, Z,/Z)

Second Isolated Output: Optional

Frequency Range:

@5V, @1m cable, 250 kHz Max

@24V, @300m cable, #8 output, 45 kHz Max

Max. Instantaneous Current Output: 3000 mA

PPR: 4 - 50000

Speed: 5000 RPM Max. std., for higher speeds, consult factory

Electronics: Fully Encapsulated, IP67**

Temperature: -40° to 100°C (150°C rotor)

Vibration: 18 g’s

Shock: 1 meter drop test

Chemical: Polyurethane enamel paint protects against salt spray, mild acids, and bases

Weight: 0.9kg to 1.36kg.

More Advantages

- Resists failures from dirt, oil, and water contamination

- Highly resistant to electrical and magnetic motor and brake noise

- If damaged, electronics can be replaced without removing rotor

- Highest rotor holding force available for crane/hoist/brake applications

- No air gap adjustment required

- Fits shafts 11mm - 85mm

- Fits Nidek FEK motors

- 4,500,000+ hour MTBF design

- Thin Profile

- Dual Flange Standard

- Marker Pulse Standard

- -40°C thru +100°C Operation Standard

- Excellent for gear motors and brake applications

- Patented Cam Screw Rotor™ eliminates rotor slipping

- Built-in rotor position guide and diagnostic check